sales@battemachinery.com

+86-371-67991755

Skype: Battemachinery

Fax:+86 371-67993277

Tel: +86 371-67991755

Sales direct: +86 15838331071

E-mail:sales@battemachinery.com

24h services

Current position: 主页 > Feeder news >

62

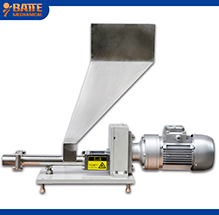

Metering feeder with core technology and independent research and development strength, has rich experience in engineering application in a number of fields and industries

91

We all know that the feeding machine of stable vibration, reliable operation, long service life, can feed continuously and evenly, the application is very wide. In we used feeding machine is the most common problem is feeding machine equipme

119

Weight loss type feeding machine is automatic production equipment intelligent computer, electronic and mechanical technology development.

193

stable vibration, reliable work, long service life, can adjust the excitation force can be changed at any time and flow control, convenient adjustment and stability.

80

A gravimetric extrusion feeders control measures the flow's weight and adjusts the feeder output to maintain the desired set point. On the other hand, a volumetric feeders, by definition, do not measure the weight of the flow.

79

A gravimetric feeder measures the flow's weight and adjusts the feeder output to maintain the desired set point.

146

You must know before buying volumetric feeders Working principle : How is running of the volumetric feeders ?Materials are discharged from the system through screw rod, the system will compare the weight loss measured per unit time with nee

190

Have you ever bought gravimetric feeder been cheated? Gravimetric feeding machine , a high degree of intelligence, screw form diversification, the screw can be according to the material to choose different types of screw, solve the bridging

137

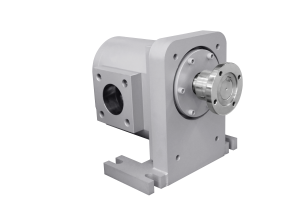

What is a melt pump? Melt pump is a main machine used to transport, pressurize and meter the high temperature and high viscosity polymer melt flow in industrial production.

©2015 Batte Mechanical Zhengzhou Co,.Ltd. All rights reserved. sales@battemachinery.com

Batte is a loss in weight feeder manufacturer, supplying loss in weight feeder, volumetric feeders, and metering feeders.

Batte is a loss in weight feeder manufacturer, supplying loss in weight feeder, volumetric feeders, and metering feeders.